Views: 0 Author: Site Editor Publish Time: 2025-10-15 Origin: Site

Ever wondered how large plastic parts are made with precision and minimal waste? A roto molding machine is the key to producing hollow, durable plastic products in various industries. In this article, well explore what a roto molding machine is, how it operates, and its importance in manufacturing. You'll learn about the process, components, and advantages of this versatile machine, helping you understand its role in creating high-quality products.

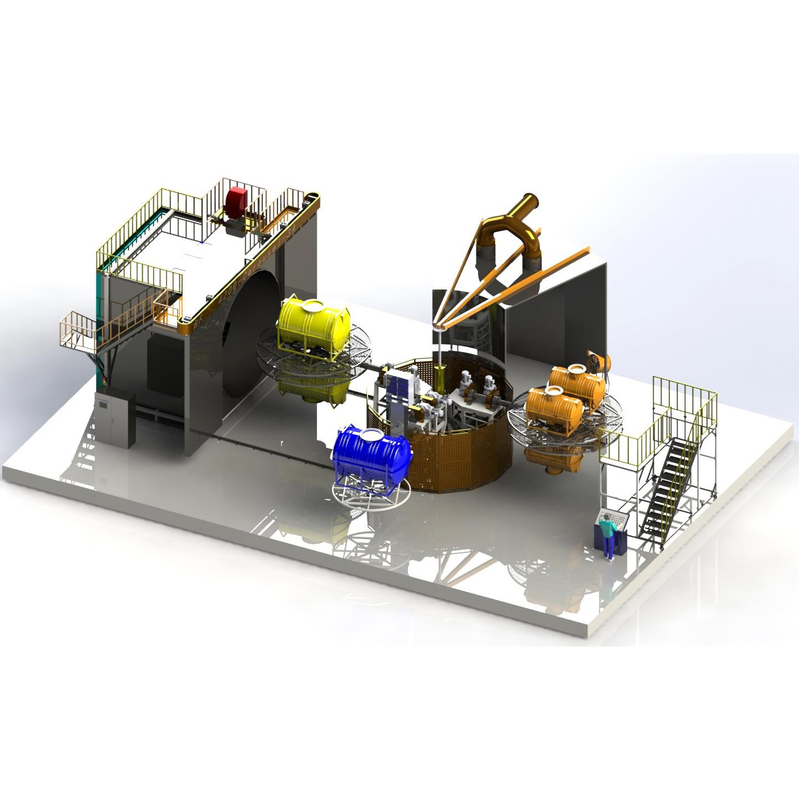

A roto molding machine is designed to produce hollow plastic products by using heat and biaxial rotation. The process begins with placing plastic resin, typically in powder form, inside a mold. The mold is then heated while rotating on two perpendicular axes. As the mold rotates, the heat causes the plastic to melt and adhere evenly to the interior surface of the mold. This rotational movement ensures that the plastic coats the mold uniformly, forming parts with even wall thickness and no seams.

Unlike injection molding, which involves injecting molten plastic into a mold under pressure, roto molding relies on the gradual heat and rotation to achieve the desired shape. This technique is especially effective for creating large and complex hollow parts that are lightweight yet strong. The roto molding machine is highly versatile, capable of producing a wide range of products, from small, intricate items like toys to large industrial parts such as tanks or playground structures.

A typical roto molding machine consists of several key components:

● Molds: Made from durable metals such as aluminum or steel, molds give shape to the final product. The mold's interior is designed to match the exact shape of the product being created, and it can be customized for specific design requirements.

● Oven: The oven is where the mold is heated. It is essential that the temperature inside the oven reaches the right level to melt the plastic, typically between 260 to 370 degrees Celsius (500 to 680 degrees Fahrenheit). The even distribution of heat is vital for ensuring consistent material flow inside the mold.

● Cooling Chamber: After the mold is heated, it moves to the cooling chamber, where the temperature is reduced to solidify the plastic. The cooling time is critical to ensure the plastic sets properly without warping.

● Spindles: Spindles are responsible for rotating the mold during both the heating and cooling phases. They ensure that the plastic material adheres evenly to the mold's inner surface and helps prevent defects such as inconsistent wall thickness or air pockets.

The operation of a roto molding machine is relatively straightforward, but it involves several precise steps to ensure the quality of the finished product:

1. Loading: The mold is first loaded with the appropriate amount of plastic resin, typically in powder form. The amount of resin used affects the wall thickness of the finished part.

2. Heating: The mold, now loaded with plastic powder, is placed inside the oven. As the mold rotates, the heat melts the resin, causing it to stick to the mold walls. The biaxial rotation ensures that the material coats the entire mold evenly, forming a uniform layer.

3. Cooling: Once the resin has fully melted and coated the mold, the mold is moved into the cooling chamber, where forced air or water is used to cool the part. During cooling, the mold continues to rotate to maintain uniform thickness as the material solidifies.

4. Demolding: Once the part has cooled and solidified, the mold is removed, and the finished part is taken out. At this point, the part may undergo further processing, such as trimming or post-finishing, to achieve the desired final appearance.

The heating phase is the foundation of the roto molding process. The mold is placed in a heated oven, where it rotates slowly on two axes. The temperature of the oven is carefully controlled to melt the plastic without degrading it. The slow rotation ensures that the material spreads evenly and adheres to the mold's inner surface. The rotation prevents the resin from pooling in one area, which would result in uneven wall thickness.

During this phase, the plastic resin forms a uniform coating on the interior walls of the mold. The combination of heat and rotation ensures that the plastic material covers all corners and crevices, which is essential for creating complex parts with smooth surfaces. The length of time the mold spends in the oven is critical; too little time results in incomplete coverage, while too much time can cause the plastic to burn or degrade.

After the mold is heated and the plastic is evenly distributed, it moves to the cooling chamber. Here, the mold continues to rotate as the temperature decreases, causing the plastic to solidify. The rotation during this phase is equally important because it ensures that the plastic cools evenly. If the mold stops rotating during cooling, the part may warp or develop inconsistencies in thickness.

The cooling time is carefully controlled, as it directly affects the final product's structural integrity. Rapid cooling can lead to cracks or deformities, while slow cooling ensures a smoother finish and stronger parts. Once the part has completely cooled and solidified, it is removed from the mold.

When compared to other molding processes such as injection molding or blow molding, roto molding offers several advantages:

● Uniform wall thickness: Roto molding produces parts with consistent wall thicknesses, whereas injection molding can lead to thicker spots or uneven distribution.

● Design flexibility: Roto molding allows for more complex shapes and designs, including parts with undercuts, which are difficult to achieve with other processes.

● Lower tooling costs: The tooling required for roto molding is generally less expensive than for injection molding, making it an affordable choice for both small and large production runs.

Clamshell machines are designed for smaller-scale operations and are commonly used in prototyping or low-volume production. These machines are compact and feature a mold that opens and closes like a clamshell. They are ideal for creating smaller parts and are well-suited for facilities with limited space. Clamshell machines offer simplicity in design and operation, making them a cost-effective choice for businesses just starting with roto molding.

Rock and roll machines are best suited for larger parts, as they rotate the mold back and forth while also rotating it on two axes. This combined motion ensures that larger volumes of plastic material are evenly distributed throughout the mold. These machines are ideal for creating durable, large products that require more material strength, such as industrial tanks and large outdoor furniture.

Carousel machines feature multiple mold stations arranged in a circular pattern. The mold rotates around the carousel, moving through different phases of the heating and cooling process. This machine type is designed for high-volume production runs, capable of making several parts simultaneously. Shuttle machines, on the other hand, use two or more molds on a platform that shuttles back and forth between heating and cooling stations. Both types of machines are ideal for large-scale manufacturing of plastic parts with high efficiency.

Roto molding machines are used across various industries due to their ability to create large, complex parts. Common industries include:

● Automotive: Used to manufacture durable components like dashboards, fenders, and fuel tanks.

● Medical: Essential in producing medical devices such as durable containers and parts for medical equipment.

● Consumer Goods: For manufacturing products like outdoor furniture, storage containers, and playground equipment.

The roto molding process can create a wide variety of products, including:

● Water Tanks: Used in both residential and industrial applications.

● Outdoor Furniture: Such as chairs, tables, and garden furniture.

● Toys: Rotational molding is often used to make durable plastic toys and play equipment.

One of the greatest benefits of roto molding is its ability to create custom designs. Whether you need intricate details or large-scale products, roto molding machines provide the flexibility to produce complex shapes and sizes. The versatility of roto molding allows businesses to experiment with unique designs, making it a preferred method for manufacturers that require customization.

The low tooling costs associated with roto molding make it an affordable option for manufacturers. Unlike injection molding, which requires expensive molds and high-volume runs to be cost-effective, roto molding is perfect for both short and long production runs. Additionally, the reduced material waste during the process further decreases overall production costs.

The ability to create complex shapes and detailed features without the need for multiple parts or additional assembly is a key advantage of roto molding. This flexibility in design enables manufacturers to create more innovative and functional products.

The uniform wall thickness achieved through the roto molding process results in durable parts that are capable of withstanding impacts, wear, and harsh environmental conditions. This makes roto molding ideal for producing parts that need to be both strong and long-lasting.

While roto molding can use a variety of materials, it is typically limited to thermoplastic resins such as polyethylene, polypropylene, and PVC. Some materials with special properties, such as high heat resistance or rigidity, may not be suitable for roto molding.

To ensure that roto molding machines operate efficiently and produce high-quality products, regular maintenance is crucial. This includes cleaning molds, checking the heating and cooling systems, and ensuring that all moving parts are functioning correctly.

One of the main drawbacks of roto molding is its slower cycle time compared to other molding techniques like injection molding. Each cycle typically takes longer, which can affect production speed. However, the roto molding process compensates for this by allowing the creation of complex parts without the need for additional tooling or assembly.

Tip: When selecting a roto molding machine, prioritize production volume, part complexity, and material compatibility to ensure that the machine meets your business needs efficiently.

When selecting a roto molding machine, consider the following:

● Production volume: High-volume production may require a more robust machine.

● Part complexity: Machines with greater control over heating and rotation may be needed for intricate designs.

● Material compatibility: Ensure that the machine is capable of processing the materials required for your product.

It is essential to weigh the costs of purchasing a roto molding machine against the potential benefits it offers. For many businesses, the low tooling cost and material efficiency justify the investment, especially when manufacturing complex parts with minimal waste.

For businesses looking to scale, it is important to select a roto molding machine that can be customized to handle different sizes and types of parts. Scalability ensures that your production can grow with your business needs.

A roto molding machine is essential for producing durable, hollow plastic parts. It uses heat and biaxial rotation to ensure even material distribution. These machines are versatile and ideal for industries requiring custom shapes and large parts.

For businesses looking to incorporate roto molding into their production process, machines like those offered by Kiddi are an excellent choice. Kiddi provides high-quality, cost-effective solutions tailored to your manufacturing needs. Explore their roto molding machine to enhance your production efficiency.

A: A roto molding machine is a machine used to produce hollow plastic products. It works by heating plastic resin inside a mold and rotating it biaxially, ensuring even distribution and uniform wall thickness.

A: The process involves heating a mold containing plastic resin while rotating it on two axes. The heat causes the plastic to melt and evenly coat the mold’s surface, creating a seamless, hollow product once cooled.

A: A roto molding machine is ideal for creating large, complex shapes with uniform wall thickness. It’s cost-effective for both small and large production runs, with minimal waste.

A: Roto molding machines offer several benefits, including the ability to create durable, lightweight products with consistent thickness. They are also cost-effective and versatile, allowing for complex designs.

A: Roto molding machines can use a variety of materials, including polyethylene, polypropylene, and PVC, depending on the product’s requirements and the desired strength and flexibility.

A: The cost of a roto molding machine can vary depending on its size, capabilities, and features. Generally, it is more affordable compared to other molding processes like injection molding.