2025-07-14 Taking proper care of your rotomolded plastic boat keeps it looking great and helps it last longer. You want your Plastic Boat Made of Aluminum Roto Molding to stay strong, safe, and ready for every adventure. Simple steps like cleaning, storing your boat out of direct sunlight, and checking for loo

Read More

2025-07-10 You use aluminum rotational mold technology for good oil tanks. This process gives you exact results and even wall thickness each time. Aluminum rotational mold tools help you make tanks fast. The tanks are strong and do not leak. You get a smooth finish and tough tanks that meet strict rules.Key Ta

Read More

2025-07-07 When you think about rotational molding, picking aluminum or steel molds can change your results. Aluminum molds are lighter and move heat fast. This means the process can go faster. Steel molds are heavier and last longer. But they usually cost more money. Cost, how long it lasts, and heat transfer

Read More

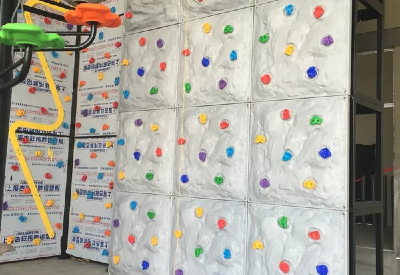

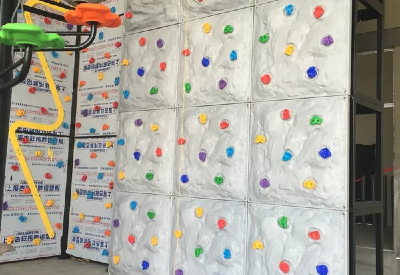

2025-06-25 Climbing walls have become a central feature in many indoor gyms, outdoor adventure parks, and recreational spaces. As the demand for diverse, challenging, and visually engaging climbing environments increases, the role of rotational molds in customizing climbing walls has become more significant. R

Read More

2025-06-25 When constructing climbing walls for gyms, outdoor parks, or recreational facilities, one of the most critical decisions is choosing the right material for the rotational molds used to create the wall panels. These materials significantly affect the durability, safety, aesthetic, and overall perform

Read More

2025-06-18 Climbing walls are a key feature in adventure parks, gyms, and recreational centers, offering both excitement and challenges for climbers of all skill levels. These structures require not only careful design but also the use of durable and reliable materials to ensure they withstand heavy usage, wea

Read More